In such a case, the reinforcement bars have to be overlapped to get the desired length. However, during the construction of reinforced concrete structures larger beams, columns, and slabs may be required.

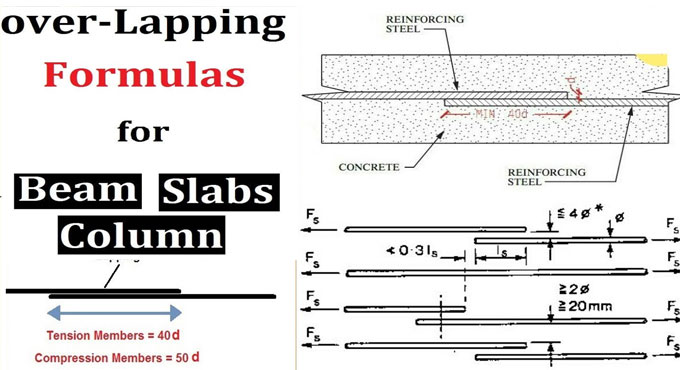

It is a general practice to manufacture the reinforcement steel bars in 12m lengths so as to ensure ease in transportation and handling. The primary objective of providing the lap is to ensure the efficient transfer of axial force from the terminating bar to the new connected bar along the same line of action in the junction. Such a process of overlapping the reinforcement bars side by side so as to obtain the desired design length is known as lapping. Lap length may also be provided when the diameter of the reinforcement bar has to be changed along the length, particularly during the reinforcement of columns. In other words, the length of overlap between the two reinforcement bars is the lap length. The lap length is thus provided to allow such lapping of the reinforcement bars side by side. In such a case, the required design length is achieved by overlapping two bars. When the reinforcement bars are placed the length of a single reinforcement bar may not be sufficient. Lap length can be defined as the length that is provided so as to allow the overlapping of two reinforcement bars thereby ensuring safe and efficient transfer of load from one bar to another. Difference Between Lap Length and Development Length General Rules for Lap Length Determination

0 kommentar(er)

0 kommentar(er)